Twin-Tube Shock Absorber and Mono-Tube Shock Absorber

Which is really better?

There are many rumors about which is better but TEIN,

the suspension specialist, puts an end to all those rumors!

The Structural Differences between Mono-Tube and Twin-Tube

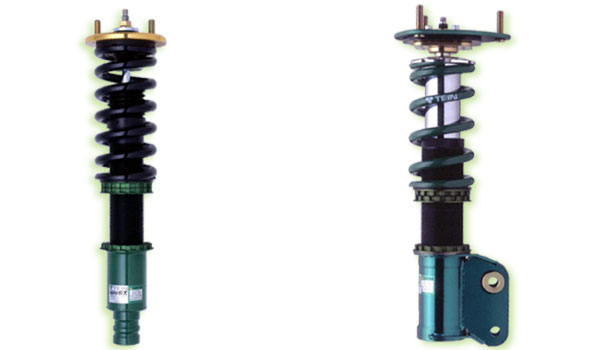

These are the mono-tube and twin-tube shock absorbers you often find in magazines etc.

For those of you who have ever thought to yourself, "I think I know the differences in the structure, but what exactly is the difference?" Here is the explanation.

The main difference between mono-tube and twin-tube systems, as shown above, is the number of tubes used for the shock absorber.

- Mono-tube: the shell case itself works as a cylinder and oil, gas, piston valve, etc are all set inside that single tube.

- Twin-tube: there is a separate cylinder set inside the shell case and the piston valve moves up and down within the inner cylinder.

Other differences in construction

Mono-tube uses a free piston that completely separates the oil chamber from the gas chamber. While for twin-tube, nothing separates the oil and gas chambers within the shell case.

The differences between mono-tube and twin-tube shock absorbers, as you can see, are not only the number of tubes but also the inner mechanism as well.

Mono-Tube - Merits & Demerits

Let's have a look at the merits and demerits of the mono-tube shock absorber.

- Merits

-

- Stable damping force can be generated continuously, because of the larger oil capacity and improved heat dissipation.

- The larger sized piston valve creates a wider area to receive pressure, and thus even a subtle damping force can be generated precisely.

- The structure allows no restrictions in installation angles.

- Oil releases heat easier as the temperature increases.

- Aeration doesn't occur because oil and gas are completely separated.

- Demerits

-

- Maintaining sufficient stroke is difficult because the oil and gas chambers are positioned serially.

- Because an injection of high-pressure gas is required structurally, the ride tends to be stiffer.

- High-pressure gas can lead to greater stress on seals and hence can cause larger friction.

- Compared with the upright type, the inverted type tends to have more friction, because it has more moving parts.

- External damage to the shell case directly affects the inner cylinder.

Twin-Tube - Merits & Demerits

Let's have a look at the merits and demerits of the twin-tube shock absorber.

- Merits

-

- It is easier to secure sufficient stroke, because the oil and gas chambers are separated and not positioned serially.

- The use of base valve enables to keep gas pressure low, allowing for a more comfortable ride.

- Low gas pressure avoids stress on seals and keeps friction low.

- Compared to the inverted type, friction can be suppressed.

- Even if the shell case is slightly damaged, the function of the shock absorber remains unaffected.

- Superior manufacturing processes allow to keep production costs low.

- Demerits

-

- Oil capacity is not as large as the mono-tube.

- Size of the piston valve is not as large as the mono-tube.

- The structure restricts installation angles.

- The oil and gas chambers are not separated, so there is a possibility of aeration.

Let's compare Mono-Tube and Twin-Tube!

Did you understand the merits and demerits of the mono and twin-tubes?

Now, let's directly compare these.

1. Ride Quality of Street Shock Absorber.

Some manufacturers say the mono-tube is superior, but is that really true?

Let's take a look back at the demerits of the mono-tube.

- Maintaining sufficient stroke is difficult because the oil and gas chambers are positioned serially.

- Because an injection of high-pressure gas is required structurally, there is a tendency for a stiffer ride

- High-pressure gas can lead to greater stress on seals and hence can cause larger friction.

- Compared with the upright type, the inverted type tends to have more friction, because it has more moving parts

- External damage to the shell case directly affects the inner cylinder.

In recent years, the ride quality has become most essential for street shock absorbers.

To ensure optimal ride quality with street shock absorbers, it is vital to have the correct settings, but also to secure the sufficient stroke.

As oil and gas chambers are divided and positioned serially inside the mono-tube, it is harder to ensure the sufficient stroke compared to the twin-tube of the same length.

A race shock absorber designed for flat circuits does not require as much stroke as a street shock absorber which always has to deal with uneven surfaces, bumpiness and other conditions of ordinary streets.

There is a direct link between the insufficient stroke and the deteriorated ride, such as sudden jolts etc, for street shock absorbers.

Let's compare Mono-Tube and Twin-Tube!

2. What is high-pressure gas?

In addition to the insufficient stroke problem, the use of high-pressure gas leads to a stiffer ride, increases friction etc. and is the main reason for deterioration in ride quality.

Some manufacturers have the base valve positioned above the free piston to lower the gas pressure, but this results in even further sacrifice in stroke and has an adverse effect on ride quality.

【Reference】 Why the mono-tube requires high-pressure gas injection.

For twin-tube, piston valve and base valve share the role of generating compression damping force, and hence there is no need to inject high-pressure gas.

However, the mono-tube creates compression/rebound damping force with just the piston valve.

The mono-tube strokes as the free piston is forced down by the displacement of contracting piston rod. If there isn't enough pressure on the other side of the free piston while this happens, the free piston would move quite easily without generating the adequate compression damping force and thus the piston rod would fully contract.

To prevent this, there needs to be enough high-pressure gas injected into the gas chamber to control the free piston movement.

When the gas chamber is filled with high-pressure gas, there will be an equal amount of pressure exerted inside the shock absorber, as the effects of Pascal's Law. In such state, there will be a high pressure applied to the oil seal, which will lead to increase in restraining force on the seal and friction.

- When there is low gas pressure.

- When there is appropriate gas pressure

Let's compare Mono-Tube and Twin-Tube!

3. Which is better suited for the street?

You never know what is lying on the surface of ordinary roads.

If something strikes the shock absorber and damages the shell case, the mono-tube, which is constructed of only one cylinder, will not be able to stroke any longer.

Considering this, is the mono-tube design really suitable for the street?

The answer, unfortunately, is "NO".

Now, let's take a look back at the merits of the twin-tube.

- It is easier to secure sufficient stroke, because the oil and gas chambers are separated and not positioned serially.

- The use of base valve enables to keep gas pressure low, allowing for a more comfortable ride.

- Low gas pressure avoids stress on seals and keeps friction low.

- Compared to the inverted type, friction can be suppressed.

- Even if the shell case is slightly damaged, the function of the shock absorber remains unaffected.

The twin-tube design can solve all the street shock absorber problems.

Furthermore, it has lower production costs due to superior manufacturing processes, compared to the mono-tube design.

Extremely important factors for street shock absorbers are high quality and reasonable price.

The twin-tube design is rather better suited for street shock absorbers.

Let's compare Mono-Tube and Twin-Tube!

4. Mono-Tube for the Circuit

Next, let's compare them for the circuit. The mono-tube's demerits seem to stand out for street use, but its full potential is exhibited on the circuits.

Let's take a look back at the merits of the mono-tube.

- Stable damping force can be generated continuously, because of the larger oil capacity and improved heat dissipation.

- The larger sized piston valve creates a wider area to receive pressure, and thus even a subtle damping force can be generated precisely.

- The structure allows no restrictions in installation angles.

- Oil releases heat easier as the temperature increases.

- Aeration doesn't occur because oil and gas are completely separated.

Racing on a circuit is extremely harsh for the shock absorber.

When racing continuously for long hours, not only the shock absorber itself generates heat but also the brake components nearby can heat up to 1,000 degrees C.

The shock absorber is fully affected by such heat.

For this reason, it is vital for circuit shock absorbers to perform well consistently even when used under tough conditions for long hours. So the mono-tube's merits are truly suited for hard-driving on circuits.

The stroke problem is not really a concern at the circuit because the flat surfaces and stiffer springs don't require as much stroke as on the street.

These are the reasons why the mono-tube design is better suited for the circuit.

The twin-tube design, on the other hand...

- Oil capacity is not as large as the mono-tube.

- Size of the piston valve is not as large as the mono-tube.

- The shell case cannot be inverted for strut type suspension.

- The oil and gas chambers are not separated, so there is a possibility of aeration.

Because of these demerits, unfortunately, we cannot say that it is considered suitable for the tough circuit conditions.

But this is only based on direct comparisons with the mono-tube. In fact, the twin-tube design TYPE FLEX, which is available on the market, landed the class victory in the 2005 Nürburgring 24Hour Race.

There is not much of a difference between mono-tube and twin-tube in terms of durability etc. Only a certain people, such as professional drivers, feel a difference in performance under very limited conditions.

Why TEIN is "Mono-Tube / Twin-Tube Construction".

As described earlier, both the mono-tube and twin-tube designs have their merits and demerits, and both have respective realms of expertise.

It is not a matter of which design is better than the other, but providing the most suitable design for the purpose is.

TEIN has a great volume of "know-how" on both mono-tube and twin-tube, accumulated over the years of experience, which enables us to provide mono-tube shock absorbers with European-car-like comfort and/or twin-tube shocks which can win the Nürburgring 24Hour Race. TEIN products have excellent quality, performance and technology that other manufacturers cannot even achieve.

TEIN is one of a few aftermarket auto parts manufacturers that produce both mono-tube and twin-tube designs.

To meet the diversified needs, it is necessary to have a wide variety of shock absorbers with various settings.

TEIN will continue to produce and provide both mono-tube and twin-tube shock absorbers, to meet the ever-changing customer needs for high-quality, high-performance and affordable price.