|

|

|

|

|

|

There's a limit to visual inspections by human…

-Results of sensory examinations by finger nails etc vary by examining staffs.

-Accuracy depends on examining staffs' physical conditions, tiredness & ability to concentrate.

-It is difficult to seek a common basis of quality standards between the plants; ordering parties & suppliers.

etc, etc, etc… |

|

|

|

- 1. [Detection]

- Ability to detect various flaws, including pinholes and linear scars/scratches.

- 2. [Versatile Detection Performance]

- Various algorithms for detecting flaws under different conditions.

*Algorithms for piston rod and insert pipe are included as standard.

*User-Settable Algorithms

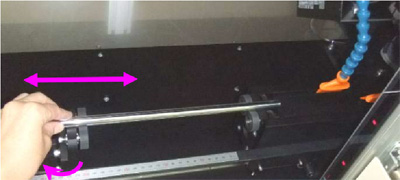

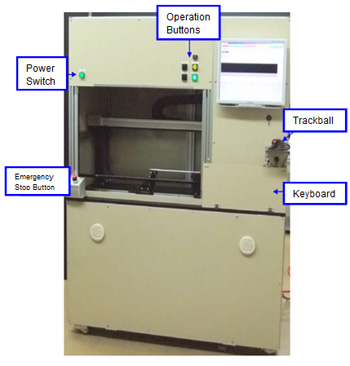

- 3. [Simple Operation / Easy Setup]

- *Push buttons to select/set diameter

Simple Operation Push buttons to select/set diameter

- *No need to set length - edge auto-detection to calculate length

Simple Operation Just place the test object onto the roller.

- *Foot Pedal to start the inspection

- 4. [Reliable After-Sales Service]

- Diskless Read-Only-Memory Computer, for smooth start-up & for easy troubleshooting / maintenance

|

|

|

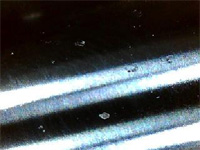

- 1. [Pinhole]

- Microscopic Image

-

- Flaw Detected

- rejects if;

0.15mm sq. or larger pinhole is found.

0.15mm sq. or larger pinhole is found.

- OR

3 or more pinholes of 0.03m sq. or larger and below 0.15mm sq. are found within 10mm sq. area.

3 or more pinholes of 0.03m sq. or larger and below 0.15mm sq. are found within 10mm sq. area.

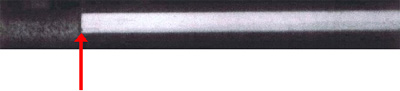

- 2. [Linear Scars ]

- Microscopic Image

- Flaw Detected

rejects if scar/scratch is deep enough for 1.5mm long HB-0.5mm mechanical pencil lead to get caught

rejects if scar/scratch is deep enough for 1.5mm long HB-0.5mm mechanical pencil lead to get caught

- 3. [Scratches]

- Microscopic Image

- Flaw Detected

rejects if scar/scratch is deep enough for 1.5mm long HB-0.5mm mechanical pencil lead to get caught

rejects if scar/scratch is deep enough for 1.5mm long HB-0.5mm mechanical pencil lead to get caught

- 4. [Dent]

- *Dent: a type of flaw with plating still remained on surface, most likely be caused when the surface was pressed/hit.

It is difficult to detect dent because of smaller luminance difference from the flawless part.

Special mode is used to detect such dent precisely, but that process requires longer inspection time.

Takt Time ø12.5 / 200mm-long : 17 seconds (*43 seconds)

*Time required when dent-detection is activated.

- Microscopic Image

- Flaw Detected

|

|

|

|

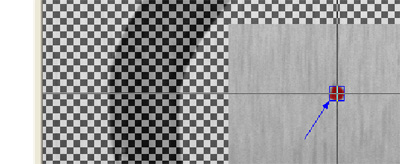

The basic principle is to binarize the image and distinguish the difference in gray value as a flaw.

In the past, this process tends to detect oil/dust residue as a flaw is the threshold is set low.

TEIN has solved this problem, after much trial and error,

by applying different algorithms specifically designed for different types of flaws. |

|

|

* Judgment of Flaw

1) Flaw Detection Algorithms

2) Binarization of Image

3) Threshold Setting

4) Local Averaging

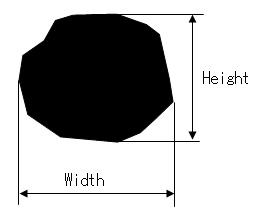

5) Height

6) Width

7) Area

8) Rectangle Localization

Judge/detect flaw, by the combined use of above.

|

|

|

|

|

|

|

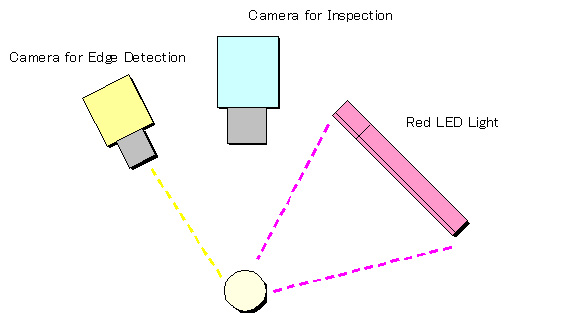

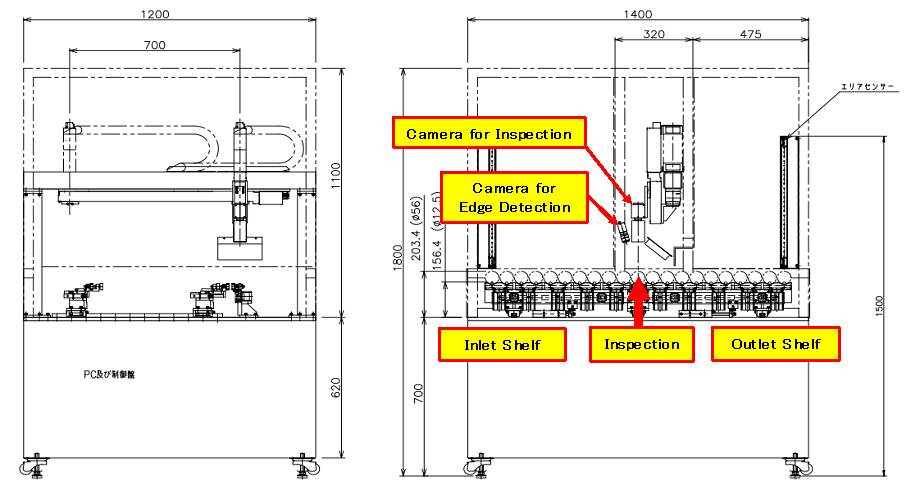

The camera for edge detection checks for difference in gray value of plated and non-plated area to determine the edge of test area.

Likewise, existence and position of rebound stopper are detected.

One of the labor-saving ways. |

|

|

|

|

|

|

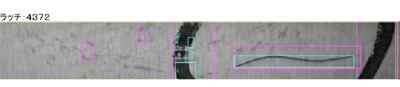

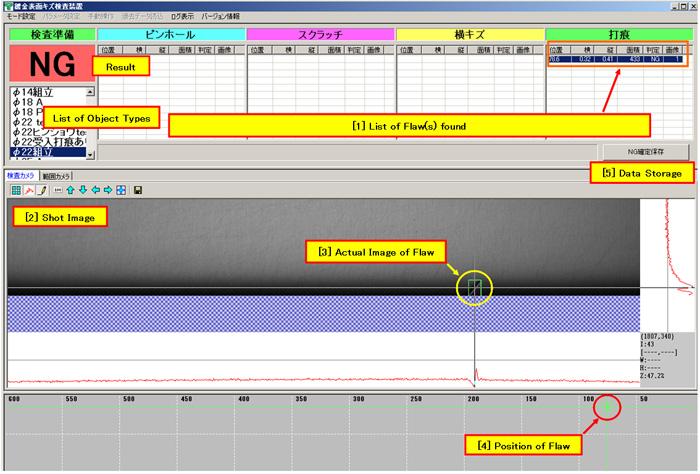

[1] List of Flaw(s) found

Position (mm), width (mm), length (mm) and area (pixel) of flaw(s)

Area : how big a flaw is, in pixels

Width & length: converted data, at 1pixel = 6.74µm

Select data to view details

[2] Shot Image

Real-time image of surface of the test object. (Binarized Image)

[3] Actual Image of Flaw

Shows the luminance difference and the disturbed wave.

[4] Position of Flaw

Distance from the edge of the test object

Example shows that the flaw is found about 80mm from the edge.

[5]Data Storage

Both pass/fail data saved automatically

Press  to save in separate folder. to save in separate folder.

Capacity : approx. 20,000 pcs (based on TEIN past records)

*vary by numbers of flaws (images)

Downloadable via USB |

|

|

|

|

|

|

|

|

|

|

|

|

| * Equipment Specifications * |

| Testable Diameter (mm) |

: |

12.5 to 56 (after hard chrome-plating) |

|

|

*Further testing/validation required for rods thinner than 12.5mm. |

| Testable Length (mm) |

: |

80 to 600 |

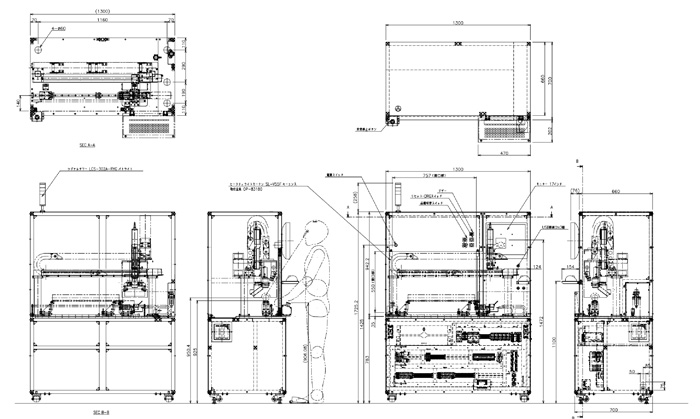

| Dimensions (mm) |

: |

1300 x 700 x 1725.2 |

| Weight (kg) |

: |

approx. 350kg |

| Power Source |

: |

Japan - single-phase 100V 50Hz

China - single-phase 220V 50Hz |

| Detection Method |

: |

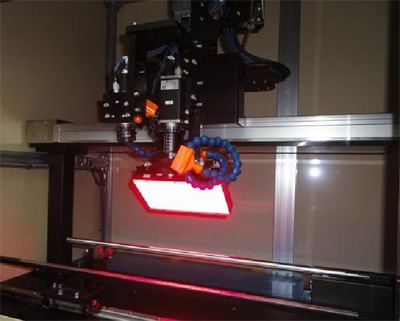

Rod Rotation / Computer Imaging Flaw Detection |

| Camera for Inspection |

: |

BASLER's shutter speed 1/5000sec |

|

|

1 pixel = 6.74µm |

|

|

Resolution 2,456 x 2,058 = 500M pixels |

|

|

MORITEX Lens |

| Camera for Edge Detection |

: |

BASLER's / MORITEX Lens |

| Setup Process |

: |

standard - manual |

|

|

Optional auto-feeder available |

| Misc |

: |

MITSUBISHI PLC (Sequencer) |

|

|

IAI ROBO Cylinder |

|

|

ORIENTAL Rotary Motor |

|

|

KEYENCE Safety Sensor |

|

|

Signal Tower Lights |

|

|

Air Blower for Dust-Proofing |

|

|

Pass/Fail Buzzer |

|

|

Automatic Data Storage (Downloadable via USB) |

|

|

|

| * Productivity * |

|

|

| Takt Time |

|

|

| ø12.5 / 200mm-long |

: |

17 seconds (*43 seconds) |

| ø22.0 / 200mm-long |

: |

24 seconds (*54 seconds) |

| <Rotation Speed : 64mm/sec (*7.5mm/sec)> |

| *When dent-detection is activated, which requires additional time because of dent's characteristics. |

| *Remarks |

| All the dirt, dust and oil residue have to be removed from the surface of the test object, prior to inspection. |

|

|

|

| |

|