Cautions for Installing EDFC Motor - 1 of 2

When installing an EDFC motor, its hexagon tip and the hexagon socket of the set screw* in the shock absorber must precisely interlock (Photos 1 and 2). Otherwise tightening them can damage the motor or bend its core shaft.

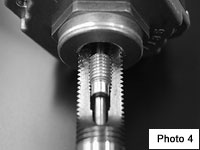

Align the set screw* flush with the top of the piston rod (Photo 3) and insert the motor's tip, making sure it fits perfectly. Lock in the motor carefully, to not bend its shaft (Photo 4). Until secure, the motor is vulnerable. Also watch out that the motor cable does not tangle up in anything and break. Both the motor and its cable cannot be repaired, and if one of them becomes damaged it will require replacing the entire EDFC motor.

* EDFC Hex Bolt for the EDFC ACTIVE and EDFC ACTIVE PRO

- Back

- Next